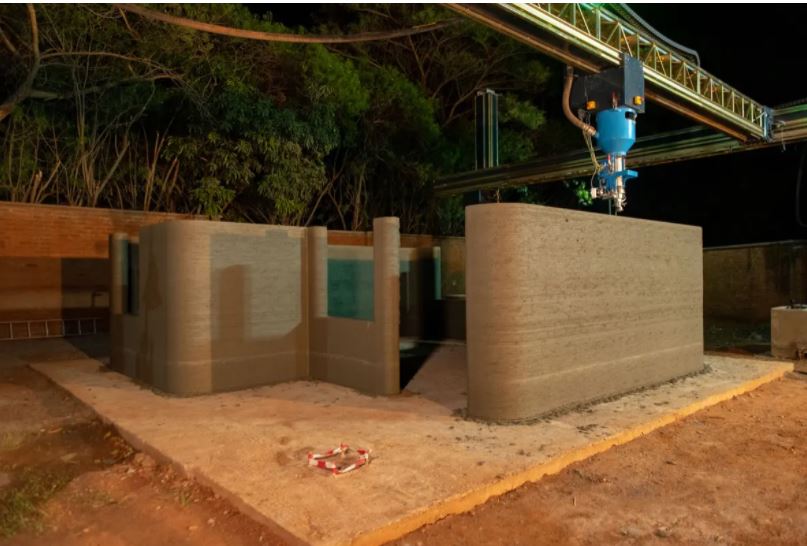

14Trees, a LafargeHolcim joint venture with CDC Group, the UK’s publicly owned impact investor, is deploying 3D printing technology at scale to build affordable and low-carbon housing and schools in Africa, starting in Malawi. The group printed the walls of a school and a house in Lilongwe to show how the method could be used as a cheap and fast way to build social infrastructure in Africa.

The walls of the prototype house were printed in Lilongwe in 12 hours, compared to almost four days using conventional methods, CDC said, while the walls of the school, built in Salima, were printed in 18 hours.

The UN’s Children Fund UNICEF estimates a shortage of 36,000 classrooms in Malawi. The joint venture, called “14Trees” said this shortfall could be eliminated in 10 years with printing, as opposed to 70 years using conventional construction methods.

With its record speed of construction and optimised material use, this technology reduces the carbon footprint for building new homes by up to 70%. Pioneering this technology in schools for the first time, 14Trees aims to address the country’s chronic infrastructure shortage while creating skilled local jobs.

Miljan Gutovic, Region Head Middle East Africa and LafargeHolcim Executive Committee member, said: “I am very excited about the work of our joint venture 14Trees, innovating in 3D printing technology to accelerate affordable and sustainable building, from homes to schools. This is a great example of our commitment to build for people and the planet. Starting in Malawi, we will deploy this technology across the broader region with projects already in the pipeline in Kenya and Zimbabwe.”

Tenbite Ermias, Managing Director, Africa, at CDC said: “The rollout of 14Trees’ world-class, cutting edge technology is going to have a tremendous developmental impact on Malawi and the wider region. It is a wonderful example of how we are investing in businesses that can support the UN’s Sustainable Development Goals.”

Using proprietary LafargeHolcim ink, this innovative 3D printing process will significantly reduce the time and cost of building housing and schools in Malawi. UNICEF estimates a shortage of 36 000 classrooms in Malawi which would take 70 years to build using conventional methods. According to 14Trees, this infrastructure gap could be bridged in just ten years using 3D printing. Partnering with a range of NGOs, 14Trees is committed to solving this chronic shortage at scale, starting with families and communities most in need.

These projects will sustain skilled job creation with the hiring and development of local experts from 3D machine operators to material specialists working hand in hand with local builders for carpentry, roofing and painting.

The walls of 14Trees’ first prototype house were built in Lilongwe in just 12 hours, compared to almost four days using conventional methods. The walls of its first school, built in Salima, were printed in just 18 hours, as opposed to several days.

Original story from Cement World